CNC corner forming machine

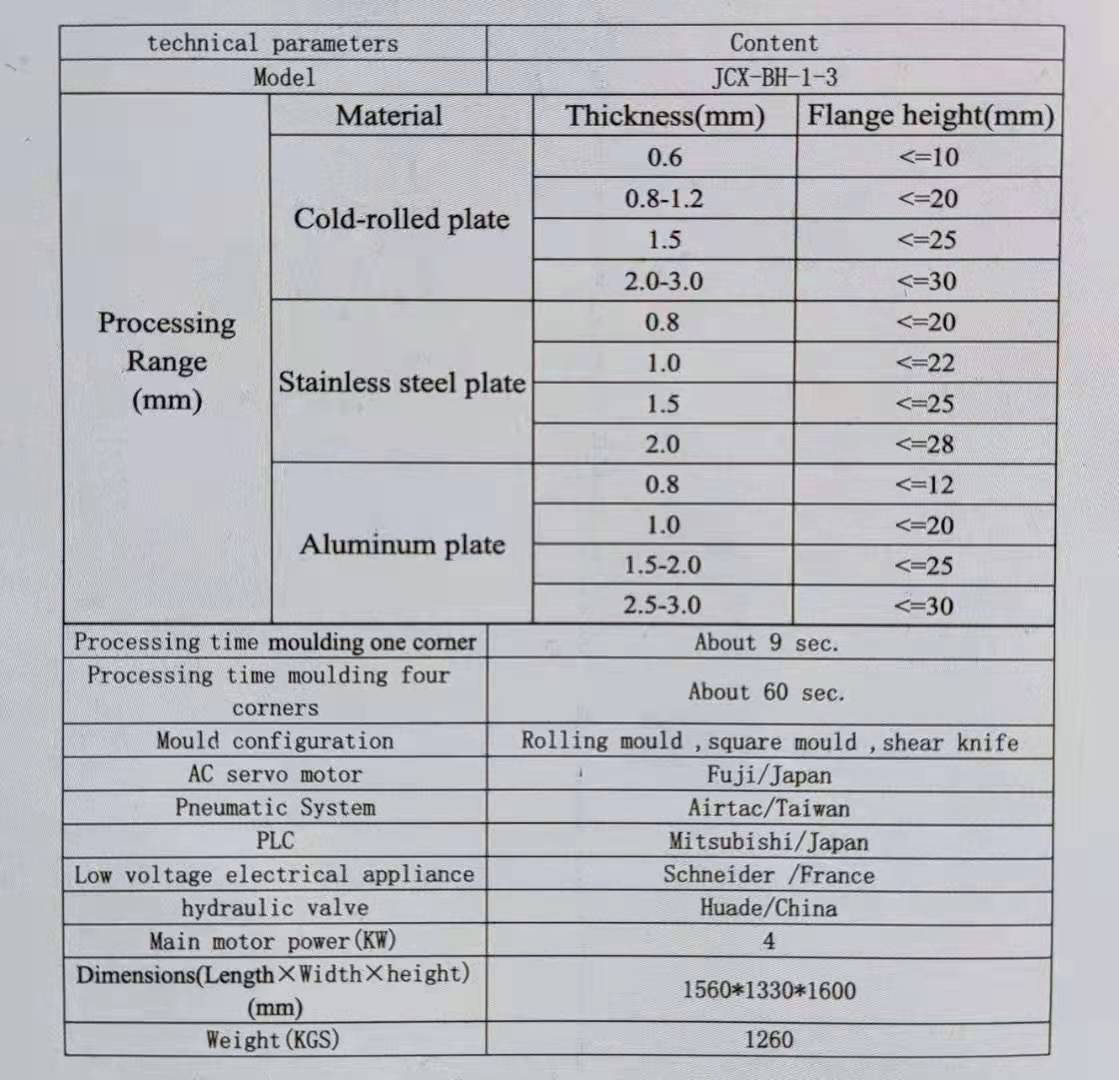

This CNC corner forming machine is suitable for the processing of door panel products such as high and low voltage electrical cabinets, air energy heat pump top covers, filing cabinets, explosion-proof electrical appliances, and outdoor air conditioners. Change the traditional corner welding and grinding processing methods, use the corner forming equipment to directly stretch and shape, and the stretched material is cut by the platform shearing knife, so that the work piece does not need to be welded and polished, and solves the high cost of manual welding, polishing and labor. , The problem of poor recruitment, and also solves the problem of long and rusty corners of welding products. The processed products are beautiful and beautiful, and the product quality and quality are improved to a level; the bending height of the work piece can be flexible and changeable within the stretching range , The thickness of the plate can be processed within the processing range, and it is suitable for processing cold-rolled plates, 304 stainless steel, aluminum plates, copper plates and other plates. The equipment is equipped with safety light curtain protection to make the production process safer and more user-friendly. The equipment mold gap adjustment is the control accuracy of Fuji servo motor, the adjustment parameters are set through the touch screen, and the PLC controls some other actions of the equipment. The equipment comes with a set of molds, which include forming rollers, forming square molds, shear cutters, lead molds, pressing plates, etc.

CNC Corner Forming Machine

CNC Corner Forming Machine

Steel Box Corner

Aluminum Corner

Stainless Corner

Design

Integrated forming, high effect, good efficiency

R and H can be change

We can design the custom mould for your different R and H request

High Speed

About one mins for four corner

Service

All lift service and mould supply

.

.